Here is a fun fact for you: People produce about 10 billion tons of concrete per year, which makes it the second most produced and consumed substance in the world. The first one is water!

Due to its stability, durability, and strength, it is the world’s most widely used material for construction. However, despite all of his advantages, there has been a lot of speculation about the fact that concrete might be actively contributing to greenhouse gas emission.

Because of this, there is a pressing need for construction and other industries to adopt and introduce environmental-friendly materials. With this in mind, the concrete industry has decided to adopt a sustainable and eco-friendly alternative – the green concrete.

What is green concrete?

Traditional concrete uses cement as the main ingredient, which requires electricity and heat to be produced. This is responsible for 50% of CO2 emissions. The other 50% comes from a very demanding process of calcination, which is the transformation of limestone into quicklime. For this reason alone, the Beyond Zero Emissions has published a report which outlines several ways to improve this situation.

One of them is the green concrete, a form of eco-friendly concrete that is manufactured and produced using waste or residual materials from different industries. It requires less amount of energy for production and thus produces less carbon dioxide. It is also a lot cheaper and more durable than traditional concrete.

The aim of this type of concrete is to lessen the burden on natural resources and increase dependency on recyclable materials. One of the multiple strategies that can be used for creating green concrete is re-using wash water to reduce water consumption. Other strategies include partial replacement of energy-consuming cement with reusable materials like fly ash, silica fume, wood ash, and many more. This is also called geopolymer concrete.

Different types of eco-friendly materials

Australia is currently the leading country when it comes to using green concrete. Australian researchers have found effective ways to use many different types of eco-friendly materials like:

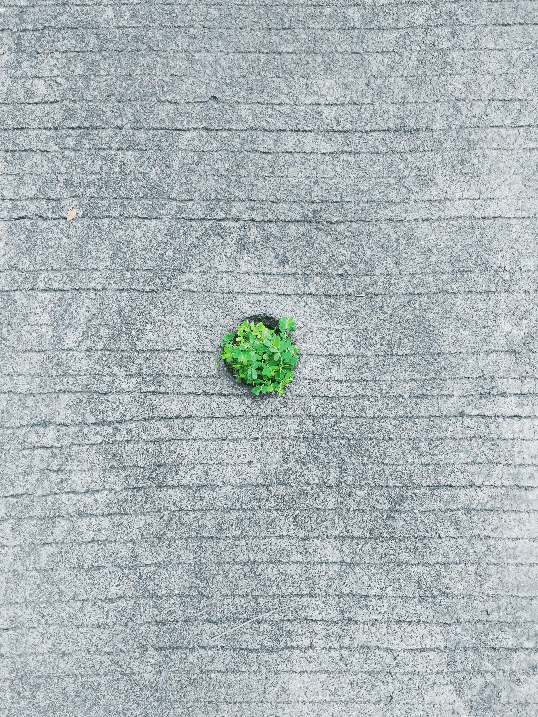

Photo by note thanun on Unsplash

Ashcrate

Fly ash is a byproduct of the combustion of coal and is discarded as a landfill. However, it can be used for manufacturing green concrete.

Fly ash is mixed with lime and water, making it strong and durable just like the conventional cement. It can make for a nice environmental-friendly alternative since it leads to reduced CO2 emissions.

Apart from this, it can also make concrete resistant to bleeding, shrinkage, and alkali-silica reactivity.

Blast Furnace Slag

This glassy and granular material is produced by quenching molten iron slag from the blast furnace into water or stream. It can replace about 70% or 80% of cement and improve the durability of concrete. Its main advantage is that the production process emits less amount of heat for hydration.

Micro Silica

This material is an ultrafine powder, which is a byproduct of ferrosilicon alloy and silicon production. It improves the durability of concrete and makes it less permeable. Its main advantage is providing stability for structures that are exposed to harsh chemicals.

Recycled Plastic

In Australia, a Ph.D. student successfully used recycled plastic to produce concrete. He replaced the steel with this new eco-friendly material and reduced the CO2 emission by 50%.

Fiber Cement

Fiber cement is a durable option that reduces the need for replacement parts and materials over a span of decades. It is created by using water, minerals, and air and using the fire to heat the mixture in a filtration process.

The design is aesthetically pleasing and uses materials that produce less CO2. Fiber cement Fiber cement has already been tested and used in the construction of high-profile structures like the Tiroler Festival Hall in Austria.