3D printing for home construction is a fast-growing industry that is allowing many companies and startups to make their way into and bring innovation to the construction branch.

The best example comes from Mighty Buildings, which last February raised $40 million in Series B funding (total investment raised so far is $70 million) to accelerate the development of its technology with which it “creates beautiful, sustainable, and affordable homes”. Founded in August 2017 by Slava Solonoitsyn, Dmitry Starodubtsev, Alexey Dubov and Sam Ruben, the company combines 3D printing, robotics and automation to produce modular homes and building components faster than traditional processes.

At the heart of the project is Light Stone Material, a thermoset composite material developed by the startup itself, which is lighter and stronger than printable unreinforced concrete, able to harden when exposed to UV light so it proves more effective for building homes. Reducing the use of steel and concrete means lowering home construction costs and allowing more people to own homes.

A studio apartment can be built in a day

Active for now only in California and headquartered in Oakland, where its manufacturing facility is located, Mighty Buildings builds homes by cutting down on labor hours (-95%) and producing ten times less waste than traditional techniques. Specifically, the company claims to be able to 3D print a 32-square-foot studio apartment in 24 hours, making the entire structure and not just the walls.

There are currently six models available in Mighty Buildings’ catalog, all equipped with a bathroom, kitchen area and appliances (washing machine, dishwasher, refrigerator, oven and microwave). The size of the houses range from 30 to 135 square meters and are made by printing only the material you need, which you can also recycle to use in subsequent constructions.

The main requirement to have a house made by the California-based company is to own a piece of property that already has an existing home and which has enough space for a new building. The costs depend on the model chosen and the environment in which you want to erect the house, while the time for the process that includes the feasibility study, site assessment, service and permitting process and installation is around 6-8 months.

Wasp and the house printed in 3D with clay

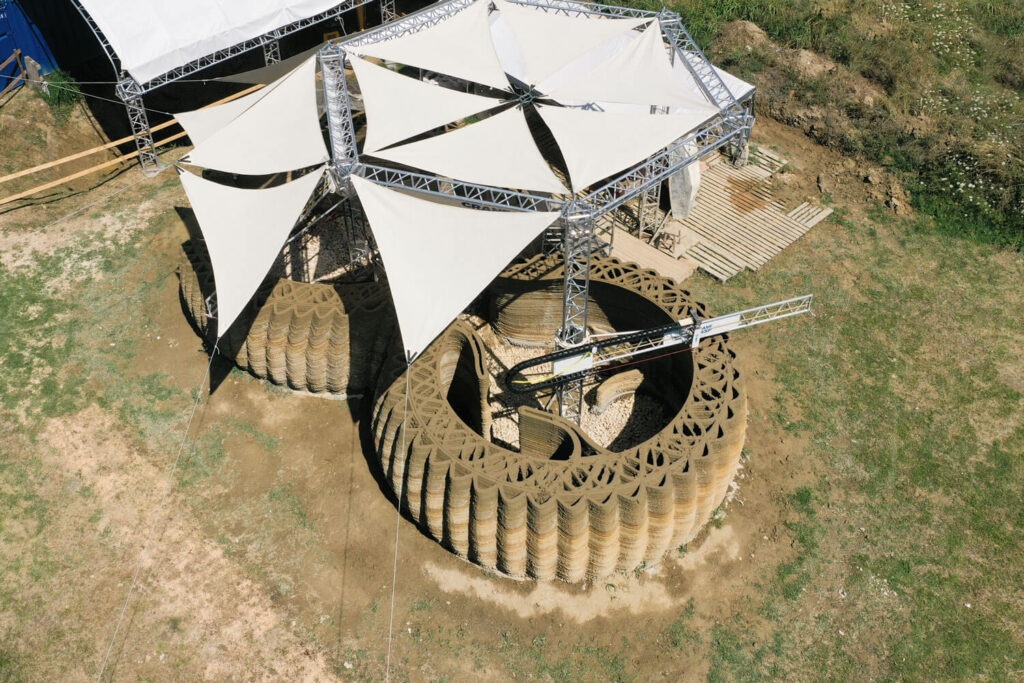

Another example, which is different but equally effective and can guarantee the construction of complete homes for every household, is made by an Italian company. Its name is Wasp and his project Tecla, innovative habitat model designed by Mario Cucinella Architects: it is a circular model of housing created with reusable and recyclable materials harvested from the local soil, zero emissions and adaptable to any climate and context.

To understand how the plan was conceived, we interviewed Massimo Moretti, founder of Wasp, the company that engineered the structure.

What were the reasons behind the Tecla project?

Wasp, which means World’s Advanced Saving Project, is a company founded in 2012 in Massa Lombarda (near Ravenna, Italy) that designs, manufactures and sells 3D printers Made in Italy all over the world. We work daily with the aim of responding to human needs (home, food, health, energy, work, art and culture) through 3D printing.

We are inspired by the potter wasp, which builds its own nest with material recovered from the surrounding environment and we produce 3D printers also of large dimensions to build housing modules with natural materials available on the territory at a cost that tends to zero. Our dream is that every person can have a home by birthright, an ecological and safe home.

WASP is a technological and cultural movement that designs sustainable development systems and models for people and companies. In 2018, GAIA, the first 3D printed house made of raw earth, was born, and now comes TECLA, the first Eco-sustainable habitat.

Tecla is composed of circular modules. Can you make housing structures of other shapes, or are there limits to the current home building system you use?

Wasp decided to print circular shapes because they are much more complex to make than straight lines and because the wasp’s nest is our inspiration. Tecla is in fact the pinnacle of advanced research between material and technology, it is the achievement of an unprecedented and unparalleled challenge that has taken the geometry of printing to its physical limit. The project represents an unprecedented perspective for construction and new settlements, in which the value of local raw materials is amplified by digital design.

The double dome solution allowed the roles of structure, roofing and exterior cladding to be filled at the same time, making the building high-performing in all respects. Right now WASP is working on a construction site in Tuscany and our client decided on a standard shape building, but with Wasp’s Crane printer, we have no shape limitations and can print quickly and collaboratively.

What types of safety systems can homes built via 3D printing rely on? Beyond the Tecla, can homes be built in areas prone to seismic activity or other similar pitfalls?

Wasp currently markets housing models inspired by the Gaia model. The printed portion is loaded only by its own weight and is used as an external buffer to the glulam structure that supports the roof. While our intent is to build fully molded buildings, at this time our technology does not allow us to provide molded portions with the ductility and strength to allow them to be used structurally in areas deemed to be at seismic risk.

What are the advantages and limitations of 3D printing in home construction? Looking to the future, 3D printing has the potential to revolutionize the construction industry, which has been tied to immutable procedures for many years?

Wasp proposes the printing of Eco-sustainable housing modules. Sustainable architecture is a cultural approach. Sustainable development, far from being a definitive condition of harmony, is a process of change such that the exploitation of resources, the direction of investments, the orientation of technological development and institutional changes must be made consistent with future needs as well as current ones. The increasing attention by the building industry to the principles of environmental sustainability and the vision suggested by the 2030 Agenda for Sustainable Development is, slowly but steadily, changing the approach to design and construction.

Investing in sustainable architecture means being far-sighted and aware that a life on a human and environmental scale is possible only by protecting the common good, starting from your own home. Crane Wasp represents Wasp’s latest technological advancement in on-site construction. The Crane Wasp 3D printing system was developed over the last few years of research with the goal of being an integral part of the Maker Economy Starter Kit project, a container designed to transport the key technologies needed to establish self-build sites around the world through the opportunities of digital fabrication. Crane Wasp represents a new way of conceiving the entire construction process, from the building site to the installation phase.

Right now, the 3D printed construction market is very much evolving but most players are focused on concrete printing while we believe in the value of sustainability and technological advancement for the good of mankind.