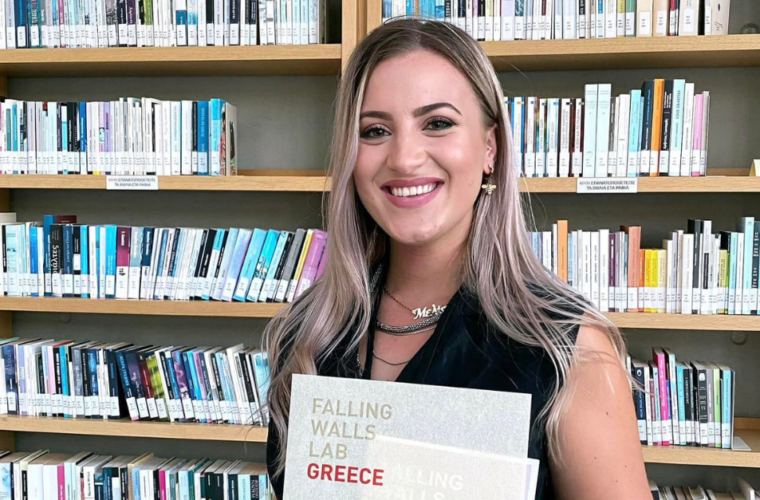

Interview with Aliki Goritsa: Pepper Vally® revolutionizes the textile industry

Pepper Vally®, a Greek textile company established in 2011 by Aliki Goritsa and Spyros Fragos, both youthful textile engineers, has revolutionized the industry by seamlessly combining the roles of designer and manufacturer.

With an unwavering commitment to innovation, quality, and sustainability, they’ve not only elevated the emotional significance of the textile sector but also transformed it into a thriving enterprise. The company places great importance on the quality and provenance of the yarns it utilizes, meticulously sourcing them from reputable suppliers. By adopting a vertically integrated production model, Pepper Vally® maintains full control over the entire manufacturing process, ensuring exceptional quality and minimizing wastage.

We engaged in a conversation with Aliki Goritsa to gain deeper insights into Pepper Vally®, its vision, and its innovative approach to the textile industry.

Can you tell us more about the unique approach of Pepper Vally® in combining the roles of designer and manufacturer? How has this approach contributed to your success in the textile industry?

Our micro-SME model is based on the freedom to do what you love -CREATE SOMETHING NEW- and not only manage and supervise. Creation is a soul-liberating process. By participating in all stages of the creation, as well as manufacturing & involving all partners as co-creators, you are aware of the “pains” & limitations. So you are “obliged” as a manufacturer and not just a designer or manager to realize the idea effectively. By mapping the solution to these everyday challenges, you create essential, original & holistic, innovative products.

What drove you to focus on e-textile technology, and how has it enabled you to address the evolving needs of modern consumers and industries?

Technical, smart, and e-textiles are the new fashion trends. More & more, we see that functionality & comfort are becoming an added value in a fashion that traditionally does not care about these features. Also, the athleisure style is becoming a trend in fashion and a luxury aspect, where we see luxury brands cooperating with sports companies to address the evolving needs of modern consumers & industries to offer added value. After all, Coco Chanel has already said this: “Luxury must be comfortable, otherwise it is not luxury”. This fits in my strong belief from my studying years already that if you want to create something innovative & useful, you have to combine things in a holistic approach, e.g.. art with science, fashion with functionality, technology with sustainability, innovation with crafted sur measure techniques.

Innovation is about how you transform the biggest challenge into an opportunity. The biggest challenge of our era is to find the essence of serving the wearer’s needs for a more qualitative way of life without creating new problems in his skin & overall health and the environment. We spent years experimenting with new fabric structures and new ways to introduce textiles & knitted products in a holistic well-being approach.

All these reasons contribute to getting involved in the smart and e-textiles world as an opportunity to combine different aspects and sectors; the result was the developed technology demonstrated by Feel More Knitwear.

FEEL MORE KNITWEAR – a proposal of smart clothes & health textile-based accessories with integrated fabric sensors that detect critical changes in the cardiovascular system.

We collaborated with programmers & electric Engineers from other EU countries and secured advisory & financial support from EU Projects.

This is the 3rd of one series of prototypes we produced after intensive research & development internally in our lab, using our expertise, our machines, and access to a lot of research material globally in different sectors (such as textiles, electronics, sports biomechanical, body mapping & healthcare); it includes sensors that record heart rate and provide physiological assessment.

Made from certified natural & renewable fibres, safe to skin for many hours, namely extra fine Merino Wool to achieve the desired elasticity and fewer seams, thanks to advanced knitting technology by using body mapping and made-to-shape knitting techniques.

Can you explain how your innovative designs and manufacturing processes align with Pepper Vally®’s mission and values as a company?

In a small enterprise, the profit scale is not the only target, as there is a strong emotional connection with the work and its details, in particular when you are involved in the manufacturing process as we are. You work every day & experiment with the materials, and you need good yarn properties to achieve the capability to work your machines while keeping productivity effective.

Our mission from starting Pepper Vally® until now is to align our beliefs for a holistic well-being approach with the products & services we offer. CONCEPTUALIZE TEXTILES from concept idea to realization. This means natural raw materials with a circular approach – f.e. easy to be sorted after use. In contrast, we use our expertise to create patterns and structures that offer the necessary longevity characteristics for easy-to-wear, easy-to-style, easy-to-care, and easy-to-re-use. This is what we call RESPECT to the supply chain, manufacturing partners, end-wearers & our planet.

How do sustainability and environmental responsibility factor into your projects and the materials you use in e-textile technology?

‘First, the raw material should be either biodegradable and renewable or recyclable, respecting the environment. Then there is the individual’s responsibility. Those involved in the production process should get paid and produce something sustainable in the long run.

Those who work in the industry should be happy and feel creative. And last but not least, the clothes should respect the health of the skin.

Introducing e-textile technology does not mean you have to wear a similar to an astronaut suit cloth. You have to introduce an innovation with added value concerning all mentioned above regarding sustainability, meaning solving a problem without creating another one.

Adding technology to textiles is very difficult, as you have to combine different sectors’ mindsets & specifications, so the design of the solution from the beginning should follow a sustainable approach from idea to implementation. Is this easy? Not at all; this is why smart textiles are still a challenge to achieve effectively.

Could you share some insights into the challenges you’ve encountered while integrating technology with textiles and how you’ve overcome them to achieve your innovative solutions?

Partnering with other sectors professionals to “exchange shoes” in a way is not easy. It takes time to study the cross-sectoral areas and just define the challenges. After this, you have to experiment and use your expertise to overcome the multiple declinations from the initial plan in the creating and prototyping process. This requires experience and easiness to work with machines and your hands, as you combine knitting technology, in our case, with electronic components & programming, and this can be time & focus demanding. Besides this, all this effort does not guarantee successful results. The motive of acquiring all your experience and the thirst to create something new and useful must always be at the forefront. In the meantime, managing your time effectively to keep the business and all its activities and products is the compensatory factor to overcoming most of the time the challenges or at least keep going.

In fashion and textiles, staying up-to-date with technological advancements is crucial. How does Pepper Vally® remain at the forefront of innovation in textiles?

Innovation is about how you transform the biggest challenge into an opportunity. To be up to date in a pool of options that sometimes are misleading, too, you have to be innovative, flexible, and above all authentic. These are the components for a small company not only to stay at the forefront but also to stay competitive in a huge international market, where big companies have the tools to convince that the products they sell are what they say they are and not what they are. Nobody asks big companies how they prove that this product is sustainably made, but for small company’s products, this is a common practice. So investing in transparency, innovation, and authenticity is the only way to stay alive and thrive.

E-textiles is still an upcoming market with huge possibilities, but it is difficult to evolve quickly due to the complexity of different aspects. The flexibility advantage of Pepper Vally’s structure and personal involvement in the design & manufacturing process are determinants in e-textile innovation. Valuable insights expertise collected from the beginning in 2011, as if you produce actively facing the challenges, you are capable of holistic & sustainable innovation beginning from the source materials & fabric until the end product specifications. To achieve INNOVATION results in e-textiles, you also need successful partnering, studying & learning the developments and cross issues of the other sectors, and combining the new knowledge & technology advancements with the experience. This does not mean you have a guaranteed result, but you have the tools and the motive to keep on.

What are your long-term goals and vision for Pepper Vally®? How do you see the company’s role in shaping the future of textiles and technology?

Establish a new business model, where good business does not necessarily mean only a stressful profit hunt but the freedom to do what we love by serving a good cause for people and society through a healthy everyday quality of life. This is not easy to achieve nowadays in order to keep the business alive, but challenge, as said before, is an opportunity for change in depth. As famous designer Yohji Yamamoto said, “you have to hate fashion to change it”.

Practical speaking, currently, we promote the results of our research and development in smart and e-textiles by finding complementary opportunities through collaborations with universities, research centres, and other companies to bring to the market products that will offer services while we like to wear anyway.

Also, we promote sales in boutiques all over Greece and abroad for our innovative resort and swimwear collection, made exclusively from Greek cotton, which is a revolution in the swimwear market, where traditionally it is the most difficult sector to replace petroleum-based synthetics with natural yarns.

We also participate in special R&D projects in collaboration with other companies to offer innovative fabrics, final products & services while preserving & evolving the sustainability & technology applications, following our business vision and ethos.

As a company founded by young textile engineers, what advice would you give to aspiring entrepreneurs or innovators looking to break into the textile industry, particularly in the realm of e-textile technology?

Personal involvement in the manufacturing process & other sectors’ mindsets, such as electronics & programming, offer aspiring e-textile entrepreneurs the creative freedom and, at the same time, the limitation to find the solution to a problem; otherwise, you risk the company’s existence. So they are something like “extreme” textiles, similar to extreme sports; you know you may “die”, but you need this liberating creation feeling of doing something for a good cause. So if you are an “extremer” and are not afraid of failure, go for it! You will never know if this will be successful each time you “jump in” to something new, but you try it anyway and keep going.