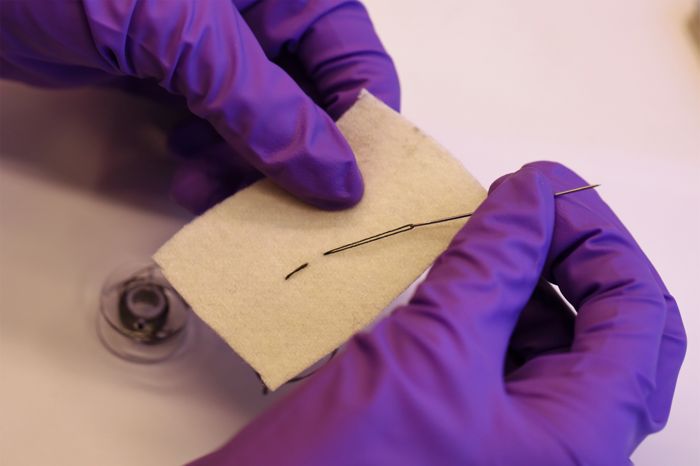

Fabrics into energy generators: A tissue that transmits electricity and becomes a uniquely shaped charger. Until some time ago, this was a utopia; now, it is a possibility, although patience is needed before we can sing victory. The remarkable innovation is thanks to a team of researchers from Chalmers University of Technology in Gothenburg, Sweden, together with researchers from Linköping University and Chung-Ang University in Seoul, who have created a silk thread coated with a conductive organic polymer that can transform the fabric into an electricity generator via a thermoelectric process.

So, is imagining a jumper powering a device to monitor one’s health in the future? We might get there, provided that experiments succeed in improving on what scientists led by Professor Christian Müller discovered. The basic concept is the conversion of temperature difference into electrical energy by the tissue, which, when connected to a sensor, can power the devices without the need for batteries.

The Swedish study is essential because of the material created: ‘The polymers we use are pliable, lightweight, washable and easy to use in both liquid and solid form. They are also non-toxic,’ explains Mariavittoria Craighero, PhD student at the Department of Chemical Engineering at Chalmers University of Technology and first author of the recently published study.

Another decisive aspect is the air resistance of the current-conducting material, which thus makes up for the instability of previous materials that are easily degraded by air and moisture. Also to be considered is another quality of the silk thread made by the researchers, which is safety, limited in the better-known inorganic semiconductors by the presence of toxic elements and heavy metals, making them unusable for devices intended to be in contact with the skin.

On the other hand, the silk thread tested proved to be well suited to textiles because ‘after seven washes it retained two-thirds of its conductive properties‘—an excellent result given the difficulties in creating stable and washable organic materials. However, as Craighero added, ‘although positive, the result needs to be significantly improved before it becomes attractive for commercialisation’.

Among the many data to be worked on is the electrical conductivity, which in the 30 square centimetre fabric stitched with the polymer is 13 Siemens per cm (S/cm), a value that is incomparable to that of an inorganic semiconductor, which can reach 1,000 S/cm. At the same time, the power generated by the material was 0.67 microwatts, a value that remained stable after 10 days but decreased by 30% after three months.

Two other points to consider concern the difficulty of producing the material efficiently outside the laboratory, while a remedy will have to be found to speed up sewing times: it took four days to make the sample fabric, far too long for 30 square centimetres.

But the potential of the discovery remains: ‘We have found the missing piece of the puzzle to make an optimal thread, also because thanks to polymers we do not need rare-earth metals, which are common in electronics,’ explains Craighero, the first signature of the EU-funded research project within the Horizon 2020 research and innovation programme.