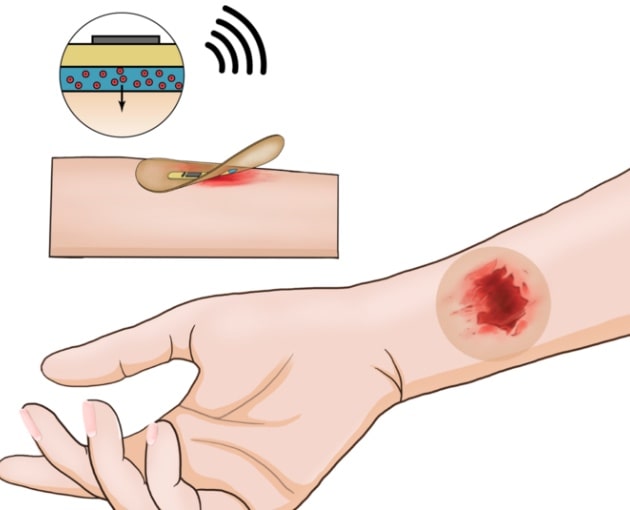

It has a wireless antenna that transmits data to a smartphone

Scientists have created a smart ‘bandage’ that uses electrical currents to heal wounds 25 per cent faster than traditional methods stimulating tissue to speed up recovery. The patch is the work of researchers at Stanford University and was described in a paper published on 24 November in Nature Biotechnology. The smart bandage is composed of wireless circuits that use the flow of electric currents and temperature sensors to monitor the progression of wound healing. According to the researchers, the device allows faster wound closure, increases new blood flow to damaged tissue, and improves skin recovery, significantly reducing scar formation.

When a person’s wound has not yet healed, or the patch detects an infection, sensors can apply increased electrical stimulation to the area to speed tissue recovery and reduce scarring. The biosensors in the smart bandage can track biophysical changes in the local environment and provide a real-time, fast and highly accurate way to measure the condition of the wound. The researchers were able to track the sensor data in real-time on a smartphone without the need for cables

Wound Care System.

“In mice, we demonstrate that our wound care system can continuously monitor skin impedance and temperature and deliver electrical stimuli in response to the wound environment,” states the researchers’ study abstract. When it comes to preclinical wound models with mice, the treatment group healed about 25 per cent faster than the control group. “In sealing the wound, the smart patch protects while it heals,” said Yuanwen Jiang, co-chief author of the study and researcher at the Stanford School of Engineering. ‘But it is not a passive tool. It is an active healing device that could transform the standard of care in treating chronic wounds.”

Researchers warn that the smart bandage is, for now, a proof of concept, albeit a promising one. However, many challenges remain. These include increasing the size of the human-sized device, reducing costs and solving long-term data storage issues – all of which are necessary to scale up to mass production if needed and opportunities arise. Similarly, new sensors not currently integrated could be added, such as those measuring metabolites, biomarkers and pH.