3D printed human body parts? Not a novelty on Earth but definitely something futuristic for Space. Yes, because Nasa, Redwire and the Uniformed Services University of the Health Sciences Center for Biotechnology (4DBio3) have sent a new 3D printer to the International Space Station, Redwire’s BioFabrication Facility, to bioprint a human knee meniscus in orbit and study the result on Earth. Ideally, this will lead to treatments for meniscal injuries that US soldiers face all too frequently. Redwire hopes to 3D print entire organs in Space, although it characterizes this as a ‘long-term’ goal.

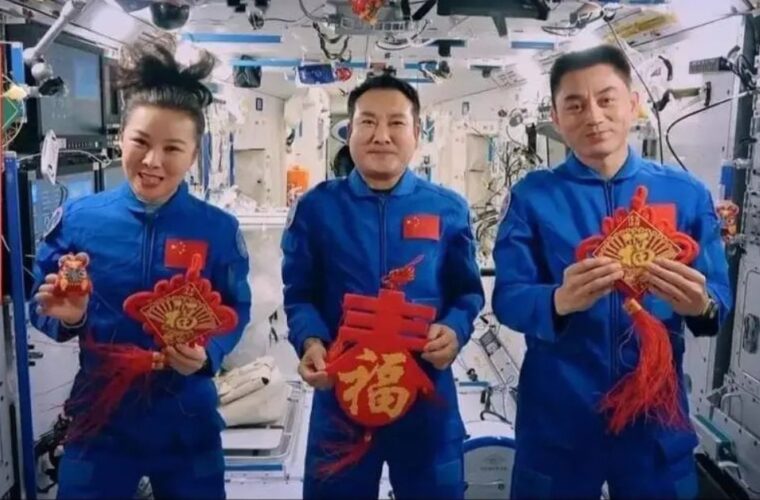

The company is very active in on-orbit experiments. For example, it uses Nasa’s Advanced Plant Habitat for a project to identify genes for compatible plants, while another investigation will demonstrate passive cooling for electronics in low gravity. The BioFabrication Facility printer is flying to the ISS aboard a refuelling rocket that took off on 6 November from Wallops Island spaceport, along with three extra loads.

3D Printer

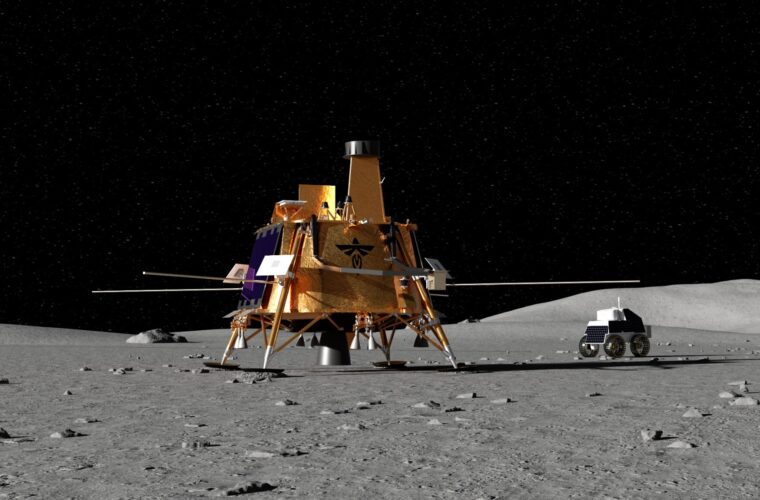

This is not the first 3D printer Nasa has used in Space. Last year, the agency took the first Redwire model beyond the sky, also on the ISS, to analyze the lunar soil and attempt to reproduce it. This could allow an accurate study of the Moon and, one day, build infrastructures suited to its environment. What is certain is that the bioprinter is more practical because it is intended to provide support for the astronauts right from the start.

If the research is successful, doctors could replace damaged body parts without resorting to donations or inorganic implants and, above all, without returning to Earth. In 2019, astronaut Christina Koch activated the BioFabrication Facility (BFF), created by the aerospace research company Techshot, based in Greenville, Indiana, to print organic tissue in microgravity conditions. Artificial organs and human tissue are just two of the many resources that may be required in future space missions. Techshot participated in NASA’s Deep Space Food Challenge, which aims to develop sustainable food options for longer human-crewed tasks. The company thinks the same 3D printing techniques used in biomedical engineering could be just as helpful in creating a food source.