Thanks to a collaboration between the European space agency ESA and Airbus, the first metallic 3D printing in space was realized on board the ISS, a major advance in the autonomy of future long-duration exploration missions. The first 3D printing in space dates back to November 2014, and since then, engineers have exploited microgravity to develop new printing materials or create structures that would be difficult to make on Earth, always using plastic materials.

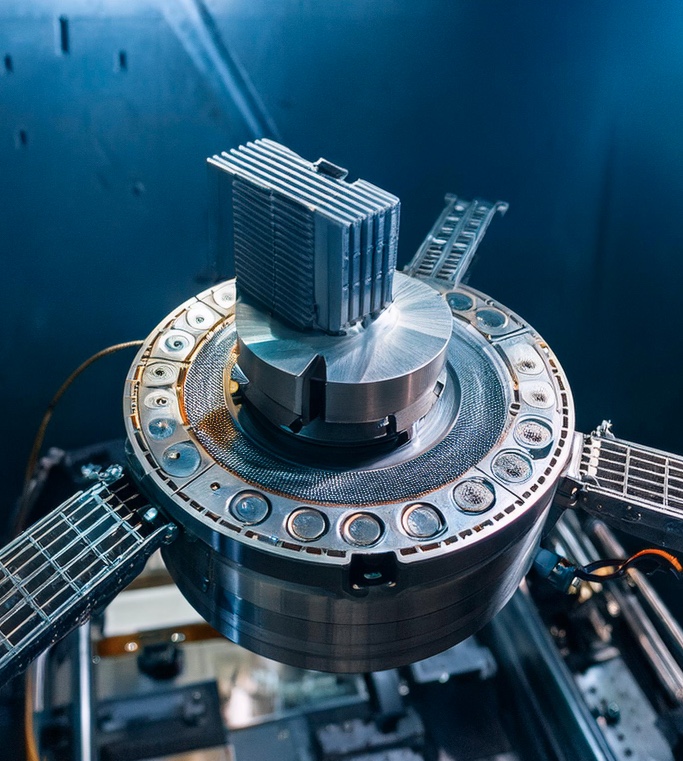

Since last February, the Metal 3D Printer has been on board the ISS, built for ESA by a consortium led by Airbus Defense and Space, including the French company AddUp, Italy’s Highftech Engineering and Cranfield University in England. The printer was installed in May in the European Drawer Rack Mark II of the Columbus module by Danish astronaut Andreas Mogensen and then put into operation to perform various tests on the printer’s individual components.

Beyond the Limits of Space

In the following months, operated by the French space agency CNES and proceeding cautiously to solve various problems, first and foremost the unpredictable behaviour of the molten metal filament during deposition, the printer began to produce its first three-dimensional object. The steel used as a medium is very resistant to corrosion; it is used for medical prostheses and water treatment and is fed as wire and heated up to 1,200 °C by a high-energy laser. To prevent oxidation of the molten steel, the printer’s internal atmosphere is vented outside the ISS before each print and then completely replaced by nitrogen. The millimetre tip of the wire at this point melts, and thanks to the surface tension of the liquid steel, it is deposited in the printing area without floating freely.

Looking for the Moon

“As exploration of the Moon and Mars will increase mission duration and distance from Earth, resupplying spacecraft will be more challenging. Additive manufacturing in space will give autonomy to the mission and its crew, providing a solution to manufacture needed parts, repair equipment or construct dedicated tools on demand during the mission, rather than relying on resupplies and redundancies. ESA’s technology demonstrator is the first to successfully print a metal component in microgravity conditions. In the past, the International Space Station hosted plastic 3D printers,” the ESA said.

One of the parameters that requires the most attention is the height of each deposited layer, which must be measured with a scan before the command for the next layer is sent. By mid-July, with the first 55 layers completed and having achieved a certain stability, it was possible to speed up the printing process and extend the working hours to 4.5 per day.

A month later, the first 3D metal print ever made in space was finally completed and will be analysed in various European laboratories, together with the other three in the experiment. In fact, the other three specimens to be printed will demonstrate different properties of the metal. The four parts will be analysed on the ground at ESTEC, the European Astronaut Centre and the Technical University of Denmark after the return from the ISS. It will help advance technologies for in-space manufacturing needs, from tooling and repairs to additive construction, opening new possibilities for future space exploration missions.