A Japanese chemical manufacturing firm has been dedicated to developing liquid biomethane derived from cow waste, aiming to utilize it as rocket fuel. This innovation could potentially offer a resolution for dairy farmers facing difficulties in waste disposal.

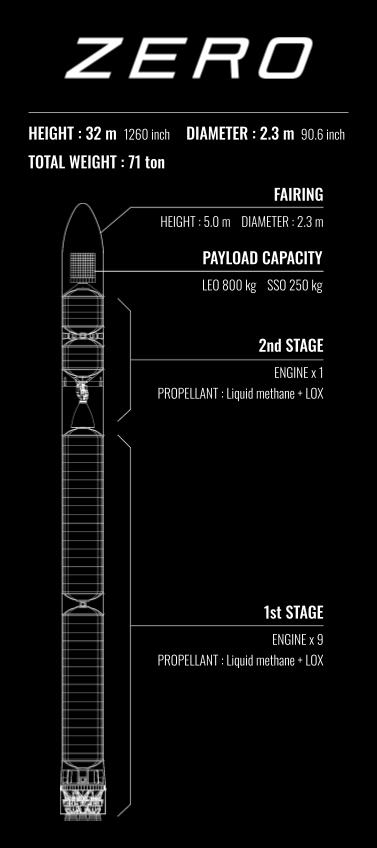

The Japanese space startup Interstellar Technologies has achieved a crucial milestone by conducting a successful test of its Cosmos engine for the Zero rocket at the Hokkaido Spaceport. This innovative rocket utilizes methane gas obtained from cow dung as its fuel, marking a significant breakthrough in the pursuit of creating the world’s first orbital rocket powered by this plentiful and sustainable resource.

The static fire test effectively activated the engine for 10 seconds, producing a robust blue flame. While the European Space Agency has previously developed a rocket engine fueled by cow dung, Interstellar Technologies is the first private company to accomplish this feat.

Liquid methane has emerged as a superior fuel choice for rocket launches due to its comprehensive advantages in price, fuel performance, ease of handling, availability, and environmental impact, making it the preferred choice for rocket companies worldwide, including SpaceX’s Starship. The engine test showcased the practicality of utilizing biomethane as a clean and easily accessible source of rocket fuel.

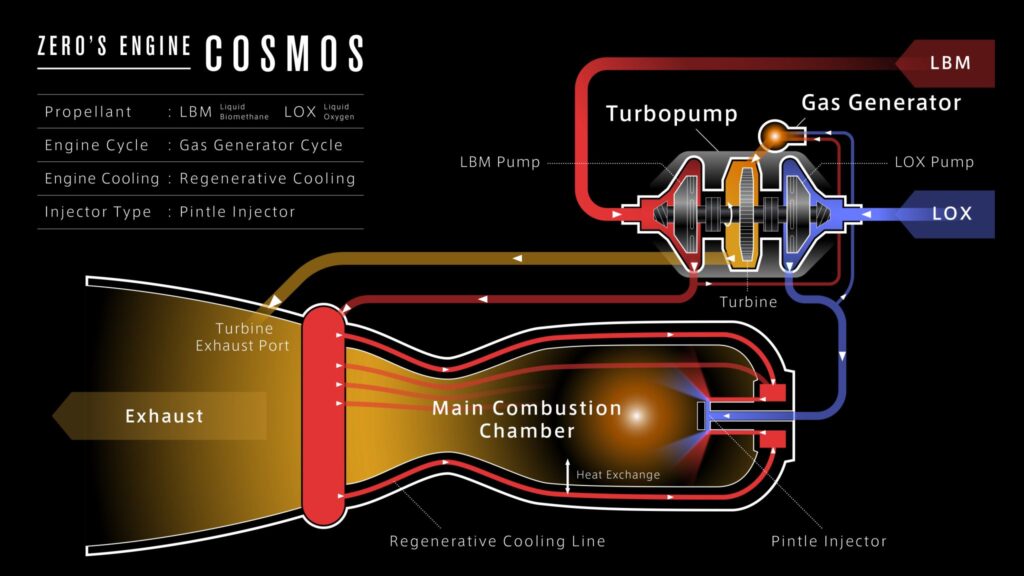

“The combustion chamber of ZERO, designed in-house, adopts the pintle injector used in SpaceX’s engines. Although pintle injectors are generally known to have limited performance, research and development efforts with Tokyo University and JAXA Space Innovation through partnership and co-creation have led to design improvements that achieve high combustion performance. As a result, the number of components has been reduced to one-tenth of conventional engines, fundamentally lowering the manufacturing costs of a rocket engine, estimated to constitute half of the overall expenses,” Interstellar said in a written statement. According to the company’s statement, the continuous series of static fire tests is positioned to advance the development and production of a 130kN-class operational model.

“ZERO operates as a liquid-propellant rocket with LBM as its fuel and liquid oxygen as the oxidizer. This marks the inaugural adoption by IST of the gas generator cycle, which burns some of the propellants in a gas generator to drive a turbopump at tens of thousands of rotations per minute and deliver the fuel to the combustion chamber at high pressure. Additionally, regenerative cooling effectively utilizes the fuel for cooling purposes within the combustion chamber walls. Tests for the combustion chamber, turbopump, and gas generator have been conducted, with plans to integrate them”. This progress is informed by the knowledge acquired during the design, manufacturing, and testing phases of a smaller 60kN-class subscale model.

The recent successes in the field of rocket propulsion mark a significant leap forward in sustainable and innovative technology. With breakthroughs in utilizing biomethane derived from cow waste as a clean and abundant source of rocket fuel, companies like Interstellar Technologies are paving the way for a more eco-friendly space exploration era. The ongoing series of static fire tests, building on insights from smaller subscale models, signals a promising trajectory toward developing a 130kN-class operational model. As private companies lead the charge in harnessing alternative fuel sources, the future of rocket propulsion appears poised for greener and more efficient advancements.