By Timothy Aeppel

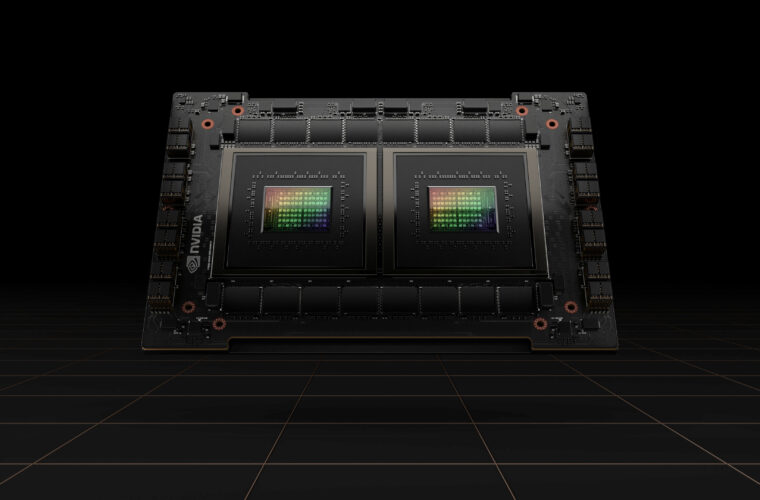

NEW PHILADELPHIA, Ohio (Reuters) – A 77-year-old factory in a hard-luck Ohio town sputtered into high gear to produce a new line of electric garbage trucks. A short drive away, construction began on a $20 billion plant that will take pizza-sized silicon wafers and make them into computer chips used in everything from data centers to cars.

The two Ohio factories – niche truck maker Battle Motors and global giant Intel Corp – show a new readiness by U.S. President Joe Biden’s administration to offer subsidies and other incentives to strategic industries such as electric vehicles and semiconductors in a coordinated effort to help American businesses compete in a global economy.

Tesla Inc said Wednesday it would shift some vehicle battery production from Germany to the United States.

While the Biden administration push, described by economists as an industrial policy, has opened opportunities for some companies, significant hurdles remain.

Reuters toured both Ohio sites and spoke to over a dozen outside experts and political leaders about those challenges, which include potential worker shortages and a growing backlash from foreign governments rushing to boost competing companies.

Once criticized by conservatives as “picking winners and losers” and by progressives as corporate welfare, a U.S. industrial policy is enjoying a rare bipartisan consensus, even in staunchly Republican states like Ohio.

Projects like Intel are a chance to “hit the reset button” on the U.S. approach to fostering key industries, said Jon Husted, Ohio’s Republican lieutenant governor, speaking as earth movers rumbled behind him at Intel’s 1,000-acre site.

Eight out of 12 Republican representatives in Ohio’s congressional delegation voted in favor of federal subsidies for semiconductor production, including the funds that will go to Intel.

“Once you explain it and educate people about these issues, it becomes something that’s easier for you to get the buy-in across political lines,” Husted said.

The 2022 CHIPS and Science Act provides $52.7 billion in federal subsidies for semiconductor production and research.

How much of that goes to Intel remains unclear. Bruce Andrews, Intel’s Chief Government Affairs Officer, said in an interview that the company hoped the money is not spread too thinly over many projects, since that would diminish its impact.

For Battle, the Biden administration’s industrial push means up to $40,000 in federal subsidies on the purchase of large electric trucks under the Inflation Reduction Act passed last year in addition to a $2.5 million tax credit from Ohio.

While both projects face immediate challenges in labor shortages and supply chain, Mark Muro, who studies industrial policy at the Brookings Institution, said a bigger issue is whether the United States will sustain this latest push.

“These programs now becoming visible have to be seen as part of a decade-long campaign to improve America’s standing in the global supply chain — as well as improving the distribution of production inside the United States,” he said.

The United States started edging towards an industrial policy beginning with the trade wars launched under the Trump administration — which focused attention on the jobs lost to foreign producers by decades of globalization.

Growing concern over the rise of China and the pandemic underscored the risk of relying on imports for essential goods. Over the past two years, U.S. manufacturers struggled to produce everything from cars to washing machines due to semiconductor and other shortages, while many types of safety and health equipment needed to fight COVID were scarce.

Russia’s invasion of Ukraine added to the anxiety, prompting the shutdown of European gas pipelines and the reduction of global grain exports from Ukraine.

PLANT TRIPLED IN SIZE

Sheer scale separates the two ventures: Intel, a component of the Dow Jones Industrial Average, employer of 121,000 people worldwide, annual sales: $79 billion. And Battle Motors, the new face of a decades-old niche maker of heavy vehicles, employer of 300, daily output: six vehicles.

One is aimed at helping the U.S. gain pre-eminence in domestic production of a product at the core of everyday life, the other a stab in the dark in applying an evolving technology to something as analog as a refuse truck.

For Battle, the federal and state incentives were a major draw in siting the factory in Ohio.

“The initial idea was that we could do this in Arizona or California,” said Michael Patterson, the company’s CEO, as he strolled through the plant.

Then he saw a key advantage in buying a factory that already made garbage trucks and adapting them to run on batteries. Other EV companies have struggled to produce vehicles from scratch.

The plant, which tripled in size after it was acquired in 2021 by Patterson’s California-based company, continues to focus on internal combustion and natural gas-powered trucks but has created a separate assembly line for electrics.

“When Battle Motors came into being, there was a little bit of skepticism (among local residents), because it was a company that produced electric vehicles and that’s something that’s brand new in this part of Ohio,” said Joel Day, mayor of the small town of New Philadelphia where Battle is located.

Many residents have since embraced green technology because it’s part of a larger wave of advanced manufacturing that is giving hope for a broader industrial revival, Day said.

But the launch of the new EV garbage trucks has been hampered by a shortage of parts and glitches in developing charging infrastructure for the trucks’ massive batteries.

Ron Cole, the fleet manager for Los Angeles’ sanitation department, which is about to begin testing five electric trucks from Battle and two other companies, said cities may in some cases need to build new power lines simply to bring in enough electricity.

The Intel factory is going up in a glistening industrial park minutes from the beltway that rings Columbus and close to other big tech companies, including Facebook, Amazon, and Google.

Creating a hub for semiconductor manufacturing far from U.S. chip hubs such as Arizona and Oregon will require developing a network of nearby suppliers and educational programs aimed at churning out workers with specialized skills.

When Asian countries were building up their semiconductor manufacturing industries decades ago, they benefited from coordinated government strategies that focused on building up production facilities as well as supply chain, Intel’s Andrews said.

“They decided 30 years ago to build up their chip industry,” Andrews said, noting that governments introduced policies to attract production plants as well as the whole supply chain.

Industrial policy still has critics. Scott Lincicome, director of general economics at the libertarian Cato Institute, said industrial policy tends to crumble into failed projects and cost overruns.

“There’s all sorts of more market-oriented reforms that could achieve the type of objectives our political class wants, without the unintended consequences of industrial policy,” he said. “None of that comes with a ribbon cutting ceremony.”

Elizabeth Reynolds, a professor at the Massachusetts Institute of Technology, said the current effort aims to boost sectors, not individual companies. Until October, Reynolds served as Biden’s special assistant for manufacturing and economic development.

In the case of zero emission vehicles, “any technology can access the tax credits for them — so we’re letting the market decide,” she said.

Andrews acknowledged that relying on government support carries risks. A future administration might pull back on projects that take years to build.

The rush to build new plants, in Ohio and elsewhere, could create a glut when these factories finally start producing.

“That’s something that all of us will have to manage,” he said.